The Future of Manufacturing: An Insight into the Industrial Blade Factory

Understanding the Role of the Industrial Blade Factory

In the fast-evolving world of manufacturing, the industrial blade factory stands as a testament to innovation, precision, and productivity. These facilities are critical in producing high-quality blades that serve various industrial applications. From cutting to slicing, industrial blades are integral to numerous sectors, including food processing, packaging, woodworking, and metalworking.

The Significance of Quality in Blade Manufacturing

At any industrial blade factory, the essence lies in delivering unmatched quality. The quality of blades not only enhances the efficiency of operations but also affects the safety and output of the entire production line. Here are a few key factors that determine the quality of industrial blades:

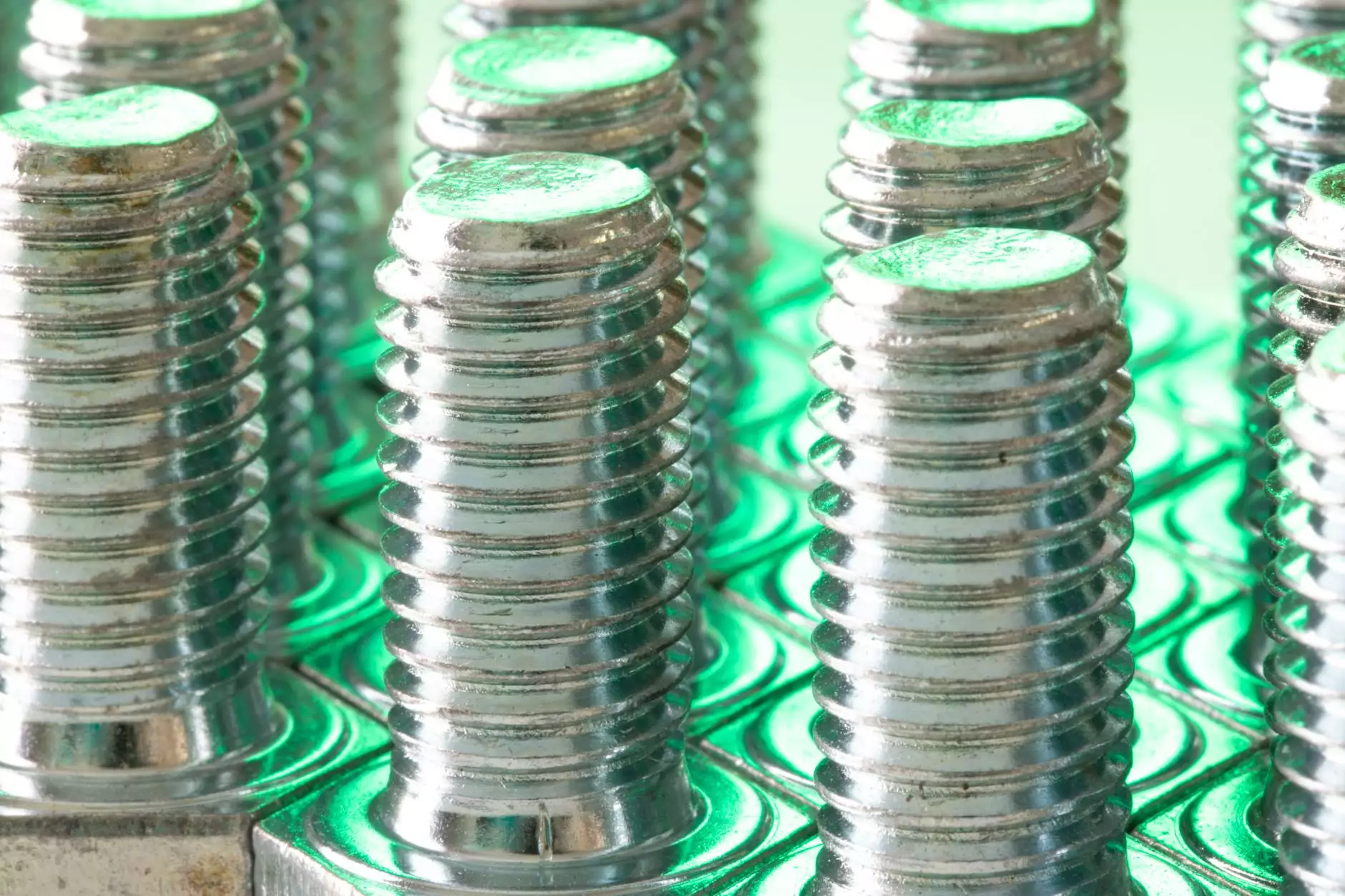

- Material Selection: The choice of material plays a vital role in blade durability and performance. High-carbon steel, stainless steel, and advanced alloys are commonly used to ensure longevity.

- Precision Engineering: Advanced manufacturing techniques such as CNC machining and laser cutting ensure that the blades are manufactured to exact specifications.

- Heat Treatment: Proper heat treatment processes enhance the hardness and resilience of the blades, making them suitable for heavy-duty applications.

- Coating Technologies: Protective coatings can be applied to reduce friction and wear, extending the lifespan of the blades.

Types of Blades Manufactured in Industrial Blade Factories

The diversity of blades produced by an industrial blade factory is impressive. Each type of blade serves specific purposes depending on the industry. Here are some common categories:

- Cutting Blades: Essential in various manufacturing processes, used for cutting materials like paper, plastic, and metals.

- Knives: Specialized knives are used in culinary and industrial food preparation, requiring precision and sharpness.

- Trimming Blades: Important in industries like textiles and automotive, these blades ensure clean and precise cuts.

- Shear Blades: Utilized for shearing operations, they require exceptional strength and durability to withstand heavy loads.

Technological Innovations in the Industrial Blade Factory

The landscape of blade manufacturing is continually being reshaped by technological innovations. Here are some key advancements that are being integrated into modern industrial blade factories:

- Automation and Robotics: Many factories have started employing robotic arms to handle repetitive tasks, enhancing speed, safety, and precision.

- 3D Printing Technology: This technology allows for rapid prototyping and the creation of complex blade designs that were previously unattainable.

- Smart Manufacturing: IoT-enabled machines and sensors provide real-time data, helping managers make informed decisions and optimize production processes.

- Advanced Coating Techniques: Developments in coating technology improve the lifespan and efficiency of blades.

Importance of Professional Services in Blade Manufacturing

In addition to manufacturing blades, industrial blade factories often provide professional services, ensuring that the blades maintain their performance over time. Some of these services include:

- Knife Sharpening: A crucial service that ensures blades retain their sharpness and cutting efficiency, which is directly linked to productivity.

- Maintenance and Repair: Regular maintenance can extend the life of blades, significantly reducing costs in the long run.

- Consultation Services: Providing expert advice on blade selection and usage can help customers make informed choices that enhance their operational efficiency.

Environmental Considerations in Blade Manufacturing

As industries strive for sustainability, industrial blade factories are also adopting eco-friendly practices. These include:

- Material Recycling: Utilizing recycled materials not only reduces waste but also lowers production costs.

- Energy-Efficient Manufacturing: Implementing energy-efficient machines and production processes minimizes the environmental footprint.

- Waste Reduction Strategies: Factories are developing methods to reduce waste during the manufacturing process, ensuring more sustainable practices.

The Impact of the Blade Manufacturing Industry on the Economy

The industrial blade factory sector significantly contributes to local and global economies. Here are some economic impacts:

- Job Creation: Factories create a substantial number of jobs, ranging from production to engineering and management roles.

- Export Opportunities: Blades produced in factories can be exported worldwide, generating revenue and impacting trade balance positively.

- Support for Local Businesses: Many industries rely on high-quality blades, and their demand supports local supply chains and services.

The Future of Industrial Blade Factories

Looking ahead, the future of the industrial blade factory industry appears promising. With ongoing advancements in technology, increasing automation, and a focus on sustainable practices, these factories are set to evolve continuously. Here are some future trends to keep an eye on:

- Customization: Customers increasingly demand customized solutions, which factories will need to address through flexible manufacturing systems.

- Digital Transformation: Embracing digital tools for inventory management, production scheduling, and customer relationship management will become crucial.

- Global Collaboration: Partnerships with international suppliers and manufacturers will enhance access to new markets and innovative materials.

Conclusion

In conclusion, the industrial blade factory is not just a place of production but a hub of innovation and excellence within the manufacturing sector. The commitment to quality, efficiency, and sustainability drives these facilities to meet the demands of diverse industries while contributing positively to the economy. The future is bright for industrial blade factories as they continue to adapt and thrive in a competitive landscape, ensuring that they remain indispensable in the global market.

For more information about our professional services and knife sharpening expertise, visit szblade.com.